|

Infrastructure |

|

|

|

On the technical arena, our new production House is spread over an area of 1400sqm. Equipped with up frontline machines and technology.

The company consists of a wide array Of production departments such as Creative & Design Department , Art Department , Digital Print , Digital Print & Cut , Foam Cutting , Plastic / Acrylic , Steel Fabrication , Aluminum Fabrication , Neon Bending , Carpentry , Screen Printing , Heat Transfer , Painting , and so forth , to enable the company to design and cater to any customer requirements with due consideration given to practicality of use , easy maintenance and cost constraints .

|

|

DESIGN STUDIO :

|

|

To furnish all possible design and art works and presentation solution to the client , the Company is encompassed with PCs consisting of Adobe CS collection, 3D MAX, Maya, CorelDRAW collection, FlexiSIGN-PRO, Rhinoceros, ArtCAM & AutoCAD soft wares . Inkjet printer, laser printer, plotters, cutters & high end scanners etc.

|

|

ART DEPARTMENT :

|

|

The art department at the factory receives the approved artwork from the design Department, or design ready fromour clint. the department analyzes the job on the basis of material and design to Decide the various department through Which the jobs will be processed and passes it on the supervisor who delegates the job tovarious department . The Art department also does cutting of Vynile , Foam , Brass , Aluminum , and Acrylic on System 56 machine.

|

|

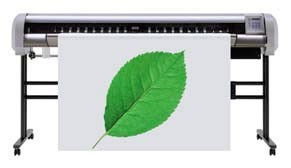

DIGITAL PRINT :

|

Epson Stylus Pro 11880 : All new Epson AccuPhoto HD screening technology All new Epson AccuPhoto HD screening technology

- Advanced screening algorithm resulting in prints with superior color and clarity

- Maximum resolution of 2880 x 1440 dpi for incredibly sharp text and line art

- Extremely accurate fine blends and photographic transitions

- Variable-sized droplets as small as 3.5 picoliters to greatly decrease print times while optimizing photographic quality

- Automatic print head alignment technology

- Enhances the ICC profiling process for ColorSync™ and ICM™ workflows

- Printers can automatically utilize two different Black ink modes – Photo Black or Matte Black. This innovative solution optimizes the Black ink density for various media types, dramatically improving the final print quality.

The standard Photo Black ink mode can be used for any media type with professional results. However, for certain Epson media such as Velvet Fine Art, Enhanced Matte, and UltraSmooth® Fine Art, using the optional Matte Black ink mode instead will dramatically increase your black optical density for even better print quality.

NovaJet 850 Large Format Inkjet Printer :is designed for speed, ink flexibility and outstanding imagequality. The NovaJet 850’s eight-color performance produces incredible color gamut and smooth tonal gradations that farexceed that of standard six-color printers.

The KODAK PROFESSIONAL Large Format 3062 Inkjet Printer :

The latest of the KODAK PROFESSIONAL Large Format 3000 series inkjet printers, this printer opens broader horizons for indoor and  outdoor display with 62-inch wide output---the widest offered yet by a major player in today's color display market. This printer bring exceptional image quality to customers who demand high-quality color output. It offers six-ink printing for specific application needs: light cyan and light magenta inks for reduced dot visibility and improved skin tones; orange and green pigmented inks for increased color gamut and reduced ink laydown. outdoor display with 62-inch wide output---the widest offered yet by a major player in today's color display market. This printer bring exceptional image quality to customers who demand high-quality color output. It offers six-ink printing for specific application needs: light cyan and light magenta inks for reduced dot visibility and improved skin tones; orange and green pigmented inks for increased color gamut and reduced ink laydown.

KEMEI OUTDOOR DIGITAL SOLVENT INKJET PRINTER : equipped with 12 pcs - 4 color , Xaar128/360 print-heads. Quality printing output on flex banner,vinyl film etc. With working size of 3.2 meter . Resolution 720 , Solvent ink CMYK .

TECHWIN OUTDOOR DIGITAL SOLVENT INKJET PRINTER : equipped with 12 pcs -6colorXaar 128/200 print-heads; Quality printing output on flex banner, vinyl film etc. With working size of2.5 meter . Resolution 360 , Solvent ink CMYKLC LM.

DGI VTII 98 DP wide printer : | | DIGITAL PRINT & CUT :

|

|

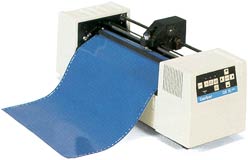

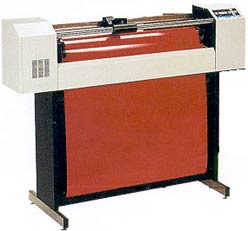

Gerber GS750plus Plotter & Gerber GS15plus Plotter :

A stepper motor-driven, sprocket plotter that uses 30" (750mm) & 15" (381mm)  perforated materials, the GS750plus™ & GS15plusprovides optimal cutting of text and graphics on all Gerber Materials and many others, perforated materials, the GS750plus™ & GS15plusprovides optimal cutting of text and graphics on all Gerber Materials and many others,  especially sandblast material . This workhorse provides positive tracking for unattended operation and reliable registration for unlimited length cutting. This is a recommended plotter for shops that cut mostly sandblast stencil. Includes an accessory kit, tangential knife tool holder and blade, pen, pounce wheel, and material roll holder . especially sandblast material . This workhorse provides positive tracking for unattended operation and reliable registration for unlimited length cutting. This is a recommended plotter for shops that cut mostly sandblast stencil. Includes an accessory kit, tangential knife tool holder and blade, pen, pounce wheel, and material roll holder .

One of the World's Best Cutting Plotters : High-Performance cutting plotter is an industry leader for sign makers, graphic artists,  auto-aftermarket professionals, countertop installers and other related users. The plotter features a maximum cutting speed of 58.5 in/sec, 4.0G maximum acceleration, and 20 to 600g selectable cutting forces, allowing users to process diamond grade, high-intensity reflective film, sandblast resist rubber, automotive window & paint protection films, self-adhesive vinyl, Amberlith™ and Rubylith™, among other media types. With the world's fastest throughput performance and superb accuracy, the machine accommodates the most demanding cutting and plotting projects and provides users with the versatility needed for a wide variety of applications. auto-aftermarket professionals, countertop installers and other related users. The plotter features a maximum cutting speed of 58.5 in/sec, 4.0G maximum acceleration, and 20 to 600g selectable cutting forces, allowing users to process diamond grade, high-intensity reflective film, sandblast resist rubber, automotive window & paint protection films, self-adhesive vinyl, Amberlith™ and Rubylith™, among other media types. With the world's fastest throughput performance and superb accuracy, the machine accommodates the most demanding cutting and plotting projects and provides users with the versatility needed for a wide variety of applications.

Automatic registration mark sensor (ARMS): The Automatic Optical Registration Mark (ARMS) sensor detects the registration marks printed alongside digitally produced images to automatically  align pre printed images to the internal coordinate system and even compensate for material expansion/contraction. These intelligent features assure the user of unsurpassed accuracy and consistently reliable operation for the most intricate die/contour cutting applications. align pre printed images to the internal coordinate system and even compensate for material expansion/contraction. These intelligent features assure the user of unsurpassed accuracy and consistently reliable operation for the most intricate die/contour cutting applications.

Optional Pounce Tool : An optional pounce tool can be purchased for perforating holes in paper for pounce patterns.

|

|

|

|

|

|

|

|

FOAM CUTTING :

|

The foam cutter is a machine controlled by a PC computer capable of  cutting any 3D objects out of extruded and expanded polystyrene foams (EPS and XPS). The cutting is performed with a resistant hot wire moving in the vertical and horizontal axes through the use of stepper motors controlled by an electronic controller connected to a PC and controlled with our FoamShaper software. cutting any 3D objects out of extruded and expanded polystyrene foams (EPS and XPS). The cutting is performed with a resistant hot wire moving in the vertical and horizontal axes through the use of stepper motors controlled by an electronic controller connected to a PC and controlled with our FoamShaper software.

Almost any 2D or 3D shape prepared in graphics software (CorelDraw, AutoCad, Rhino3D, etc.) can be loaded in FoamShaper

and cut in foam in minutes! All our units can be equipped with TurnTables, Lathes, ShapeWire Tools and other additional add-ons making them truly versatile and limited only by the operator's imagination.

see samples of our works:

|

|

|

|

|

|

|

|

CNC ENGRAVING & ROUTER :

|

|

CNC column engraving machine type characteristic

Domestic first promotes entire series each kind of specification the column engraving machine, satisfies your different processing request . engraving machine, satisfies your different processing request . The carving speed is suitable quickly for the circular cylinder, three-dimension CNC bed lathe is made of cast steel, analyzed and designed with FEA, relieving stress, so the working table is more stable Working table is vacuum system. The table can vacuum different kinds of material, and it is divided into eight working areas. Each area can be used single or together with others which could save the energy and improves the working effect. The carving speed is suitable quickly for the circular cylinder, three-dimension CNC bed lathe is made of cast steel, analyzed and designed with FEA, relieving stress, so the working table is more stable Working table is vacuum system. The table can vacuum different kinds of material, and it is divided into eight working areas. Each area can be used single or together with others which could save the energy and improves the working effect.

|

|

|

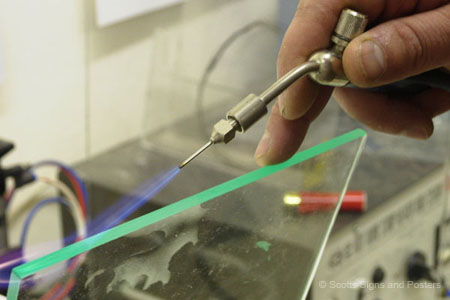

NEON ART & LIGHT :

|

We have a fully equipped neon department for blowing and gassing of neon tubes.

The facilities include a neon bombardier and gas Charger along with special burners for glass heating, bending and fusing.

see samples of our works:

|

|

|

|

ACRYLIC DEPARTMENT :

|

The plastic department manufactures, Installs and does cutting of Steel, Brass, Aluminum, Acrylic and Stencil cutting , channeelnme letters fascia and the base . And also equipped with biggest HEAT-LAMP VACUUM APPLICATORS forming machine with bed size of 3.2 m x 1.8 m for molded sign types , biggest ACRYLIC BENDING MACHINE 2.5 m , biggest ACRYLIC HEATER MACHINE 2.5 m. & Aluminum, Acrylic and Stencil cutting , channeelnme letters fascia and the base . And also equipped with biggest HEAT-LAMP VACUUM APPLICATORS forming machine with bed size of 3.2 m x 1.8 m for molded sign types , biggest ACRYLIC BENDING MACHINE 2.5 m , biggest ACRYLIC HEATER MACHINE 2.5 m. & ACRYLICFLAME POLISHER : ACRYLICFLAME POLISHER :  The machine can polish acrylic up to a thickness of 15mm in one pass. This heavy duty machine The machine can polish acrylic up to a thickness of 15mm in one pass. This heavy duty machine allows up to two operators to work simultaneously to polish 10mm in one pass. allows up to two operators to work simultaneously to polish 10mm in one pass.

|

|

|

METAL DEPARTMENT :

|

|

It is equipped with guillotine sheet cutting and pending machine along with Punching machine and lathe .inert atmosphere Aluminumwelding machine are used for Aluminum welding . This department provides facility for working on all Aluminum letters and paneling as well as the different types of Brass, Stainless and other sheets.

|

|

CARPENTRY DEPARTMENT :

|

|

The carpentry department is equipped with Aluminum, dibond hydraulic rolling machines for cutting and routhing wood and produces base plates for wooden signs, moulds.

|

|

PAINT DEPARTMENT :

|

|

|

|

HEAT-LAMP VACUUM APPLICATORS :

|

|

Our Heat and Vacuum Applicators machines allow multiple ply l ay-ups to be formed into shape quickly and easily. They are designed to form the carbon fibre by allowing the individual plys to slip against each other and produce accurate parts free from any stress wrinkling (Marcelling). The infra red heating used heats the carbon fibre quickly and evenly resulting in reduced production times and is zoned to give uniform heat distribution. ay-ups to be formed into shape quickly and easily. They are designed to form the carbon fibre by allowing the individual plys to slip against each other and produce accurate parts free from any stress wrinkling (Marcelling). The infra red heating used heats the carbon fibre quickly and evenly resulting in reduced production times and is zoned to give uniform heat distribution.

The machine is used to apply decorative engineered laminates to Aircraft interior panels such as sidewalls, bulkheads and seating shells.

The very efficient shortwave infra red radiation heating system is used to soften the laminate prior to forming and the vacuum membrane system forms the laminate to the surface of the panel.

The machine is used by subcontractors to the industry, airline and third party maintenance shops.

The machine is also used in train and bus applications such as applying graffiti resistant films to train interiors. Heat and Vacuum Applicators are also used to apply laminate furnishings such as car roofs and dashboards in the automotive and truck industries. The machine is also used in train and bus applications such as applying graffiti resistant films to train interiors. Heat and Vacuum Applicators are also used to apply laminate furnishings such as car roofs and dashboards in the automotive and truck industries.

Our Heat and Vacuum Applicators machines for use in a wide variety of industries : Access flooring panels / Advertising panels / Aerodynamic mouldings for trucks / Agricultural units / Aircraft composite forming / Aircraft honeycomb bonding / Aircraft interiors / Animal housing / Antarctic accommodation units / Architectural panels / Automotive anti-vibration mountings / Automotive interiors / Bathroom modules / Bus and Coach interiors / Camper trailers / Caravans /Carbon fibre composites / Chicken incubators / Cold Stores / Composite doors / Decorative foil laminating / Dog kennels / Door manufacture / Flexible heat shielding /  Form work panels / Furniture manufacture / Hot Drape forming of composites / Incubators / Jetty units / Kiosks for various applications / Lead shielding / Marble laminates / Marine panels / Military accommodation / Motor homes / Noise attenuation panels / Office partitions / Photographic mountings / Pig breeding units / Plywood forming & laminating / Quilting / Radar equipment shelters / Radome repairs / Refrigeration stores / Re-locatable accommodation / Re-locatable accommodation units / Re-locatable medical units / Re-locatable office units / Re-locatable school units / Roofing panels / Sandwich panels / Satellitesolar panels / Satellite dishes / Scouring pads & cleaning pads / Shower modules / Signs / Soft Foam Laminating / Structural laminated roof supports / System building panels / Telecommunication shelters / Thermal insulation panels / Traffic control & direction signs / Trailers / Train interiors / Truck bodies / Truck cab interiors / Truck trailers / Underfloor heating / Veneering / Wall insulation panels / Whiteboards / Worktop laminates / X-Ray shielding / Yacht interiors . . . Form work panels / Furniture manufacture / Hot Drape forming of composites / Incubators / Jetty units / Kiosks for various applications / Lead shielding / Marble laminates / Marine panels / Military accommodation / Motor homes / Noise attenuation panels / Office partitions / Photographic mountings / Pig breeding units / Plywood forming & laminating / Quilting / Radar equipment shelters / Radome repairs / Refrigeration stores / Re-locatable accommodation / Re-locatable accommodation units / Re-locatable medical units / Re-locatable office units / Re-locatable school units / Roofing panels / Sandwich panels / Satellitesolar panels / Satellite dishes / Scouring pads & cleaning pads / Shower modules / Signs / Soft Foam Laminating / Structural laminated roof supports / System building panels / Telecommunication shelters / Thermal insulation panels / Traffic control & direction signs / Trailers / Train interiors / Truck bodies / Truck cab interiors / Truck trailers / Underfloor heating / Veneering / Wall insulation panels / Whiteboards / Worktop laminates / X-Ray shielding / Yacht interiors . . .

|

|

|

|

|

|

|

HEAT TRANSFER DEPARTMENT :

|

|

HEAT PRESS MACHINE FOR PLATES: The digital heat press is special  desigined for satisfying the fashion pursuing people who pursue the individuation of plates. it is based on heat transfer princioles. choosing the special heat transfer foil and it can transfer the various motifs on heat transfer foil to the surface of plate. desigined for satisfying the fashion pursuing people who pursue the individuation of plates. it is based on heat transfer princioles. choosing the special heat transfer foil and it can transfer the various motifs on heat transfer foil to the surface of plate.

HEAT PRESS MACHINE FOR MUGS : The digital heat press is special desigined for satisfying the fashion pursuing people who pursue the individuation of mugs. it is based on heat transfer princioles. choosing the special heat transfer foil and it can transfer the various motifs on heat transfer foil to the surface of ceramic mug, glass mug, metal bottle and so on.

HEAT PRESS MACHINE FORT-SHITRS : The digital  heat press machine is special desigined for satisfying the fashion pursuing people who pursue the individuation of garments. it is based on heat transfer princioles. choosing the special heat transfer foil and it can transfer the various motifs on heat transfer foil to the surface of cotton t-shirts, garments, socks, sports clothes, and so on. heat press machine is special desigined for satisfying the fashion pursuing people who pursue the individuation of garments. it is based on heat transfer princioles. choosing the special heat transfer foil and it can transfer the various motifs on heat transfer foil to the surface of cotton t-shirts, garments, socks, sports clothes, and so on.

|

|

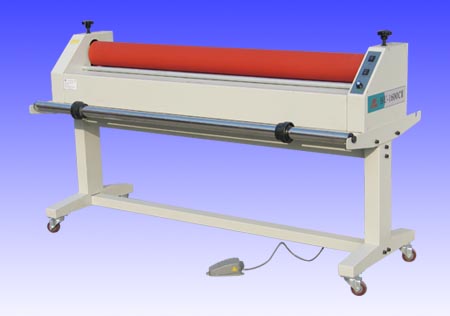

LAMINATION MACHINE :

|

|

With the expertise of our skilled professionals, 3 Roll To Roll - Hot & Cold lamination machines, width 160cm , 70cm & 30cm, height for roller: 2.5CM.

this machines used for the laminating and protection of material like identification  card, historical accounts, photos, pictures, credit cards and important documents. After laminating, the material has the unique function like water resistance, alteration resistance, damp resistance, worm resistance and mildew resistance on general acid-base. What''s more, it is stiff, smooth and pleasing to one''s eyes, since it has good transparency.for Indoor & outdoor use. card, historical accounts, photos, pictures, credit cards and important documents. After laminating, the material has the unique function like water resistance, alteration resistance, damp resistance, worm resistance and mildew resistance on general acid-base. What''s more, it is stiff, smooth and pleasing to one''s eyes, since it has good transparency.for Indoor & outdoor use.

GLUER MACHINE :

This gluing machines is one of special equipment to manufacture corrugated board. It is mainly used for coating and binding of board.

PAD PRINTING :

This pad printer is used for the surface pressing of curved face, flat, and irregular object, particular object with elegant, delicate effect and small area, and roughness where other pressing methods can’t work. This machine is widely used for glass, metal, board, plastic, and rubber. For example electronic appliances, dolls, toiletries, production date, industrial products, bottle hoods, pens, electronic components, capacitance, ballast resistor, switches and buttons. irregular object, particular object with elegant, delicate effect and small area, and roughness where other pressing methods can’t work. This machine is widely used for glass, metal, board, plastic, and rubber. For example electronic appliances, dolls, toiletries, production date, industrial products, bottle hoods, pens, electronic components, capacitance, ballast resistor, switches and buttons.

HOT ST AMP PRINTING : AMP PRINTING :

top quality embossing, engraving,foil stamping and hot foil stamp machine for all stamping and printing needs.

We also offers customized logo printing, foil stamping dies, foil printing, album imprinting and monogram engraving services to promote your business.

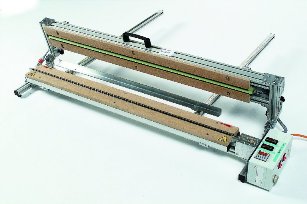

ELECTRICAL STRETCHING EQUIPMENTS : Electrically driven stretches silk screen fabric in all directions automatically , Pre-loaded screen roll minimizes fabric loading time, Process fabric up to 5500 mm in length, Sophisticated design & structure guarantees consistent tensile strength across fabric Electrically driven stretches silk screen fabric in all directions automatically , Pre-loaded screen roll minimizes fabric loading time, Process fabric up to 5500 mm in length, Sophisticated design & structure guarantees consistent tensile strength across fabric

EXPOSURE UV LIGHT MACHINE : The image is printed on special plastic paper, called film. Then this crazy machine uses light to burn the film onto silk.

FLAT-BED SCREEN PRESS MACHINE : Semi-Automatic, With the flat-bed press, WE offers a cost- effective solution for every screen print, large or small, low- or high-volume. it prints on paper, vinyl, foils, plastics, metal, glass, transfers — just about anything flat — with pinpoint (.001-inch) accuracy. effective solution for every screen print, large or small, low- or high-volume. it prints on paper, vinyl, foils, plastics, metal, glass, transfers — just about anything flat — with pinpoint (.001-inch) accuracy.

LARGE FORMAT FLAT BED PRINT MACHINE UP TO 1.5X12M :

this machine can print on roll or sheet like wood , textile , paper, vinyl , foils , plastics, metal, glass

Cylinder screen printing machine : Cylinder screen printing machine :

FRONTIER DRYER : The Dryer is engineered for heavy-duty, constant production. Its rugged construction and advanced design make it exceptionally versatile and able to with stand the most relentless constant production. Its rugged construction and advanced design make it exceptionally versatile and able to with stand the most relentless

It will handle any media 1.5m width . roll & sheet such as vinyl, mylar, tissue, paper, cardboard, plastic, wood, alcabound , fiberboard and more.

rapid and thorough drying of almost any kind of ink.

FLASH DRYER : freely wheel, It is a important equipment in  printing process, especially in multi-color printing.you can dry the ink quickly to print next color by flash dryer. you needn’t wait ink to dry in printing if you have it. printing process, especially in multi-color printing.you can dry the ink quickly to print next color by flash dryer. you needn’t wait ink to dry in printing if you have it.

Full 500 X 600mm heat opening.

The screen is washed with high powered hoses.

|

|

|

|

|

|

|